Monolith Start-Up Procedures for Ceramic Honeycombs in RTOs

Based on past experience, Lexco has noted that “Fast Heating Up” of Ceramic Monoliths causes high stress in the single blocks and can cause cracking. Heating up of blocks means that one side (the entrance of the hot air) becomes hot, while the underside remains cold. Whenever the thermal gradient of the block is higher than 180°C (324°F), thermal stresses will strongly increase the risk of cracking.

RTO operating characteristics which have shown cracking in structured media:

- one shift operation (daily reheating and cooling)

- high energy VOC’s (8 grams or more per cubic meter)

- irregular ignitions of VOCs in the bed (CO could be dangerous)

- periodically fast heat-up ( higher than normal temperatures in the combustion chamber)

- fast cooling down (spraying water on the media).

We are also aware that flame temperatures of burners can reach temperatures significantly higher than 1200°C (2192°F). When these high temperature flames reaches the surface of structured ceramic packing, the flame will cause high thermal stresses or in the case of other ceramic materials, melting.

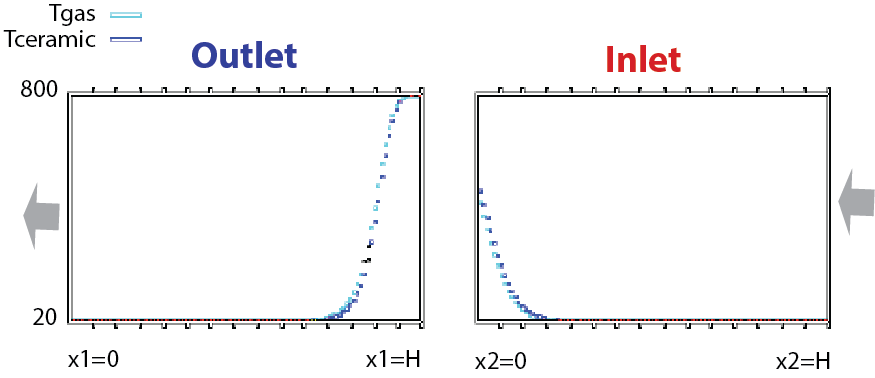

The Temperature-Graph during the first cycles of the start-up of an RTO (Figure 1) shows what occurs when you begin with a temperature of 800°C (1472°F) in the combustion chamber.

Figure 1 shows us that

- nearly the whole temperature gradient (720°C or 1296°F) takes place in the top layer of the media (3 scales mean 300mm or one block length).

- the long cycle (210seconds) causes high temperature difference between inlet (the right canister) and outlet (the left canister).

- the remaining 4 media layers do not take part in the temperature exchange during the initial phase of the start-up process.

Figure 1: Temperature at Start up – Flow Direction from right to left. The horizontal Scale shows the bed Height (in 100mm steps resp. in 3.93 inches steps) of a 5 layers bed. The vertical scale shows the temperatures (Tgas and Tceramic) over the bed height (H=1.5m or 4.92ft). Valve time: 210 seconds.

Start-Up Procedure

To keep the thermal stress within an acceptable level we suggest following procedure:

- If possible install above AND below the top layer of ceramics a thermocouple to monitor the temperature difference of the block. Try to keep the temperature gradient (difference between the two measuring points) of the top layer within 180°C (324°F).

- In the first phase of the start-up, the temperature of the combustion chamber should be only 200°C (360°F) higher than the inlet temperature of the gas.

- Run the shortest possible cycle time to prevent high temperature difference between heating up and cooling down cycles. Valve cycle time should be about 30-60 seconds.

- When you measure an increase in the temperature of 100 °C (180 °F), in the lower thermocouple, increase the temperature in the combustion chamber. Measure the time to this point – it will give you the rate how fast you can go up with the combustion temperature. When you don’t have a measurement of temperature at the underside of the top block, then use the outlet temperature (at the beginning of the outlet cycle) as measure. When you recognize a significant increase in the outlet temperature (it is very important to make the measurement within the first 5 seconds of an outlet cycle) you can expect that the temperature profile in the bed is even enough to allow an increase in the combustion temperature.

- Increase the combustion temperature at a rate of 0.1°C per second (0.2°F per second) which is equal to 6°C per minute (12°F per minute) or better if a higher rate given in step 4. If step 4 provides a much slower rate than 0.1°C, then use that rate. Increases of the combustion temperature should be so that the temperature profile in the bed remains even. Also, run this process at shortest possible cycle time. When you finally reach the regular combustion temperature you can increase the cycle time to the regular cycle within one step. The regular temperature is then in the bed and changing the cycle time cannot influence the temperature profile in a dangerous way.

Gas Stream: We suggest running the whole start up procedure at the highest possible gas stream.