Monolith Installation Guidelines

The installation of monolith is quite simple but there are a few factors to consider that can increase the life of the media.

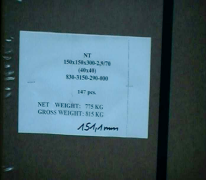

Each skid is labeled with the material and the cell size (picture 1). Use this label to determine the block type and installation order. Some blocks will be labeled with an installation line and a number painted on the top (picture 2). The number refers to the cell size and the color represents the material.

Note: Not all blocks will have installation lines.

The purpose of the line was for ease of installation however we found that it was not necessary (picture 3). The line can be installed in the same direction but is not required and is used primarily in small square units with very close canister tolerances. More importantly, at 1500 ºF each block will expand 1 millimeter (picture 4). The block pictured indicates how much the material can expand at operating temperatures. Avoid pushing blocks to tight into the insulation or canister walls. Blocks installed too tight can cause premature cracking due to thermal expansion stress.

The compression strength of the martial is extremely high. Stacking the skids is limited more by the local safety rules than the strength of the material and can be stored outside in any weather as long as the temperature is above freezing. Workers can walk on the material with no fear of crushing the block (picture 5).

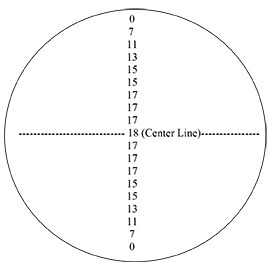

Guide for Installing Monolith in Circular Canisters

When installing a square monolith in a round canister certain procedures need to be followed. Be sure to install only the number of blocks per layer as designed or it will appear that there is not enough material for the final layer. For example the diagram identifies the number of monolith to be installed in each row.

Begin installing from the center line and work outward in each direction. Each block shuld be tight to its neighbor but allow room for expansion at combustion temperatures.

At 1500°F, each block will expand 1 millimeter. Avoid pushing blocks too tight into the insulation or canister walls.

Each skid is labeled with the material and the cell size. Use this label to determine the block type and installation order as indicated from the design.

The compression strength of the material is extremely high. Stacking skids is limited more by the local safety rules than the strength of the material and can be stored outside in above freezing temperatures. Workers can walk on the material with no fear of crushing the block.

It could be necessary to place some sort of packing around the edges of the monolith to insure air does not by-pass the media. Saddles or insulation will suit this purpose. These photos show how insulation can be packed around the blocks to keep the media in place and avoid gas by-pass.

Picture 1

Picture 2

Picture 3

Picture 4

Picture 5

Picture 6

Picture 7