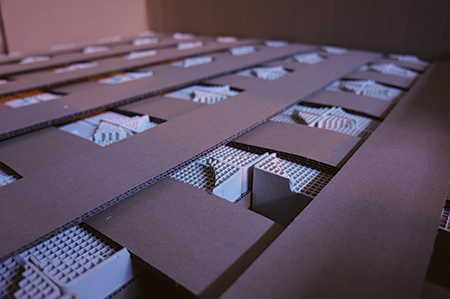

S-Type Spacers: Ceramic Honeycomb Block with Integrated Spacer to Improve Flow and Efficiency

S-type spacers provide substantial benefits for blocks:

- The integrated spacers are manufactured before applying the sintering process to the blocks, so a product free of internal stresses is produced.

- Spacing between the blocks prevents a blockage of cells by ceramic walls above it. This partial blockage occurs in different sections of the beds depending on their relative position of the blocks to each other and disturbs uniform flow.

- The spacers allow uniform flow throughout the cross section of the heat exchanger beds, improving the thermal energy recovery.

- The spacers allow a cross flow between each layer in all directions, improving the uniformity of the flow. Even a partial blockage of cells in some areas caused by dust can be overcome by this cross flow without problems.

- Applications that contain particles in the waste gas utilize this type of block, as the maintenance intervals for cleaning have improved significantly.

- The symmetrical shape of the integrated spacers reduces thermal stresses in the block and increases lifetime.

- The outer supporting areas of the blocks distribute the load in a practical way and are not subject of wear by local eroding as had occurred with conventional tablet shaped spacers.

- The specific design of the spacers is protected by the manufacturer of the blocks.

Available materials: LA10, NT, HT, HTH, CR20, CR30 and MK20

Corresponding product code: LA10S, NTS, HTS, CR20S, CR30S, MK20S

Standard dimensions [mm]: 150 x150 x 150 and 150x150x300 (other dim. on req.)

Spacers are available in all standard cell geometries from 13×13 cell to 60×60 cell

Integrated spacer adds additional length to overall dimension of monolith (i.e. 308 mm long)

The block geometry was developed with the following background:

Honeycombs installed with a gap between layers has advantages compared to layers of conventional blocks with flat cross sections:

- avoid blockage caused by cell walls directly overlapped by subsequent cell walls

- increased homogeneous flow distribution in areas of differing flow rates

Application of S-type geometries vs. conventional blocks results in:

- applications with dust show reduced blockage of channels

- lower pressure drops – for a longer period

- better distribution – better heat exchange

Packaging