Natural Gas Savings with Monolith Heat Exchange Media

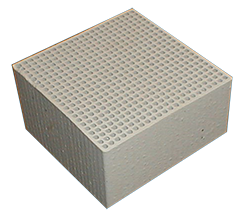

Monolith heat exchange media can provide substantial energy savings over traditional saddles. Below is an illustration of a typical application.

Bed Designs:

Monolith:

LA10 43 Cell

Bed Depth: 4′

TER: 95.4%

Gas Usage: 20.6 cft/min

Saddles:

1″ Saddles

Bed Depth: 8′

TER: 93.4%

Gas Usage: 34.8 cft/min

Results:

Annual Gas Cost:

Saddles: $73.163.52/yr

Monolith: $43,309.44/yr

Benefits:

Saddle bed requires 8′ bed depths whereas the monolith is only a 4′ bed depth, this also can provide benefits in other ways was well. The unit can be smaller: less steel and insulation, cheaper shipping, smaller unit. With half the bed height the “puff” of untreated air during valve cycling is less, this improves destruction efficiency of the unit without changing any other parameters.

Unit Parameters:

Gas Volume (scfm): 20,000

Chamber Size: 80 ft2

Number of Chambers: 2

Tin: 100°F

Tcomb: 1500°F

Cycle time: 180 sec

Usage:

Runtime: 100% Annually

Gas Pricing: $4.00 per 1000 cft