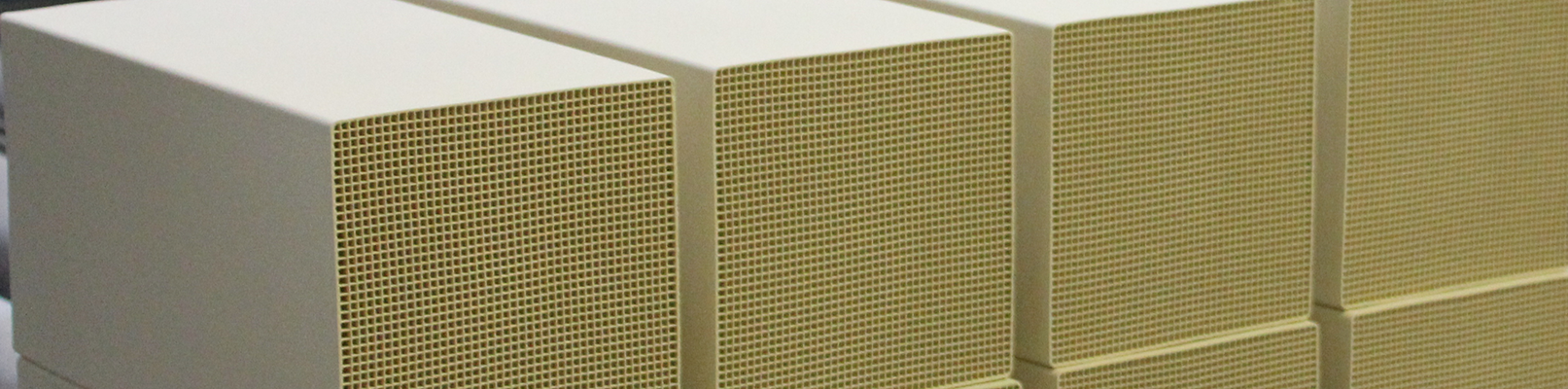

Our Monolith Heat Storage Media for RTOs:

Advantages Over Other Structured Media and Random Packing

Our monolith can increase flows of existing RTOs or reduce the media volume of new units compared to any other structured or random packing. Monolith provide the lowest pressure drop, yielding lower energy costs without sacrificing capacity. With the greatest surface area of all available heat exchange media, monolith provide more efficiency per unit of volume than any other packing.

LA10 Monolith

LA10 was developed to be our most popular monolith and competes with low cost imports; it has excellent heat storage capacity, and offers the highest TER per dollar. It has low thermal expansion thus good thermal shock resistance. This material can be used in a wide array of applications.

NT Monolith

This material utilizes high purity alumina which is excellent in acid resistance and most alkali situations. This is our heaviest block and has the highest energy recovery per cubic foot.

MK20 Monolith

MK20 is designed for high thermal shock applications. It is used in situations when there may be in-bed combustion, top layers close to the combustion chamber, or in horizontal units. It can also be used when the total bed height is less than 4′. MK20 is also recommended when bed cleaning and maintenance are frequent as it can be removed, washed and replaced with ease.

CR Monolith

CR stands for chemical resistant. This block is specific to high alkali situations and has excellent alkali resistance for those situations. Developed in cooperation with the wood industry, CR has become the industry standard for systems with alkalis from wood-fired dryers, or any system that processes salts, potassiums or have other alkalis in the process exhaust.

HT/HTH Monolith

HT is a high temperature, high mullite media used in applications where combustion temperatures exceed 1800°F. It has good chemical resistance.

Cell Sizes

We manufacture monolith in many different cell structures to fit the needs of each individual RTO. Lower number cells identify larger cell openings. All of our blocks are 150mm x150mm (we do manufacture special sizes for unusual circumstances (i.e. 175mm or half-length blocks). The number of cells along the 150mm dimension determines the cell designation. Therefore, a 25 x 25 cell will have 25 cells along the 150mm length. 25 and 32 cell blocks have large free space percentages and large cell opens making them ideal for dirty applications. 43×43 cell is by far our most common monolith and we carry an extensive inventory of 25, 32, 40, 43 and 50 cell blocks.